Support Knowledge Base - Inboard engine builds

Moderator: Bill Edmundson

- Mr Hot Rod

- Posts: 1069

- Joined: Thu Mar 03, 2005 2:40 pm

- Location: Chelsea, Quebec, Canada

- Contact:

Re: Inboard engine builds

Yes, its a stock sled, 114 HP, 597cc cylinder reed induction. The pyramidal frame construction and front and rear suspension were superior to anything that preceded it. At the time, this was a limited edition consumer version of Blair Morgan's '02 snocross sled. The shortened tunnel and beaver tail housing over the rear of the track was a one-year only feature.

The idea here was a planning, archive and reference tool. By all means, document your build in your own thread and reference it here. I usually post content on our website and link to it from here.

There is an alternative to the high cost of turnkey marine engines. Your engine building skills can help you stay on budget.

____________________

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

The idea here was a planning, archive and reference tool. By all means, document your build in your own thread and reference it here. I usually post content on our website and link to it from here.

There is an alternative to the high cost of turnkey marine engines. Your engine building skills can help you stay on budget.

____________________

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

- jenko

- Posts: 936

- Joined: Sat Mar 19, 2011 2:50 am

- Location: Pine Mountain . Vic . Australia

- Contact:

Re: Inboard engine builds

my thoughts on engine building are to maximize volumetric efficiency over your rev range or maximizing torque over all rev ranges.The stroke of the engine will determine where peak torque is achieved.The cam and head porting and manifolds have some effect on your usable rev range (small long manifolds for low rev ranges large short for high rev ranges)

lumpy high overlap cam for maximizing high rpms and smooth idle cam for maximizing low rpms

In a car you pick your gearbox ratio and diff ratio to suit your engine .

In a boat you pick your gear ratio and prop to suit your boat

what I have found over the last summer is a 12 '' prop starts to lose efficiency around 4500 rpm

which is well suited to 350 long stroke v8s not so for short stroke v12 peak torque around 5700rpm

my choice smaller prop or gear down the trans .

Or stroke the crank by 3/8''to shift the peak torque down by 1000 rpm and increase pitch on 12'' prop

(I am not unhappy with the v12 performance but I am going for this choice)

Doesn't matter what engine you choose if its not geared right it will be a dog in car or boat

Then there is the brass welch plugs to be fitted I use a copper head gasket but not really necessary, spark shielded alternator and starter probably not required on mpfi engines

I shall post some engine shots if interested

lumpy high overlap cam for maximizing high rpms and smooth idle cam for maximizing low rpms

In a car you pick your gearbox ratio and diff ratio to suit your engine .

In a boat you pick your gear ratio and prop to suit your boat

what I have found over the last summer is a 12 '' prop starts to lose efficiency around 4500 rpm

which is well suited to 350 long stroke v8s not so for short stroke v12 peak torque around 5700rpm

my choice smaller prop or gear down the trans .

Or stroke the crank by 3/8''to shift the peak torque down by 1000 rpm and increase pitch on 12'' prop

(I am not unhappy with the v12 performance but I am going for this choice)

Doesn't matter what engine you choose if its not geared right it will be a dog in car or boat

Then there is the brass welch plugs to be fitted I use a copper head gasket but not really necessary, spark shielded alternator and starter probably not required on mpfi engines

I shall post some engine shots if interested

- Mr Hot Rod

- Posts: 1069

- Joined: Thu Mar 03, 2005 2:40 pm

- Location: Chelsea, Quebec, Canada

- Contact:

Hot Rod's propeller test data

Hi Peter. Engine shots would be appreciated !

Here is a graph with the Hot Rod's propeller test data. 4500 RPM is the sweet spot. We're running 12% overdrive and OJ propellers. Peak torque is reached at 70 MPH @ 4500RPM. WOT is still unknown. The hull is very stable at high speed.

Negative slip may be due to a following current or a strong following wind. We'll have to rerun the numbers as we've installed an air/fuel ratio meter and have made some jetting changes.

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

Here is a graph with the Hot Rod's propeller test data. 4500 RPM is the sweet spot. We're running 12% overdrive and OJ propellers. Peak torque is reached at 70 MPH @ 4500RPM. WOT is still unknown. The hull is very stable at high speed.

Negative slip may be due to a following current or a strong following wind. We'll have to rerun the numbers as we've installed an air/fuel ratio meter and have made some jetting changes.

- Hot Rod Propellers (PDF)

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

Last edited by Mr Hot Rod on Fri Feb 04, 2022 8:49 pm, edited 2 times in total.

Re: Inboard engine builds

I have posted some negative slip numbers also.

Example:

a prop is measured as 16x14 with a medium cup.

You do the math for the 14 pitch and get your estimated speed per your RPM. simple math.

However, the cupped prop advertised @ 14 pitch is actually running like a 16 pitch.

The voodoo here is that nobody can accurately measure cupping, nor its effect on pitch.

We know its there, we know what it does, we just cant measure it, nor can we put it on a graph.

And there enlies the rub.!!!

Example:

a prop is measured as 16x14 with a medium cup.

You do the math for the 14 pitch and get your estimated speed per your RPM. simple math.

However, the cupped prop advertised @ 14 pitch is actually running like a 16 pitch.

The voodoo here is that nobody can accurately measure cupping, nor its effect on pitch.

We know its there, we know what it does, we just cant measure it, nor can we put it on a graph.

And there enlies the rub.!!!

- Bill Edmundson

- Posts: 12618

- Joined: Wed Nov 23, 2005 6:45 am

- Location: Birmingham, AL, USA

- Contact:

Re: Inboard engine builds

Paul

Your numbers reflect what I've noticed from peoples info. SRPM for a 12" prop is best around 4500 RPM., if the prop is in good shape. After that I think you start to see blade tip cavitation. You may get a little more MPH. But, not much. If you want to turn a lot more SRPMs then go down in dia. and up in pitch or cup.

Just my thoughts.

Bill

Your numbers reflect what I've noticed from peoples info. SRPM for a 12" prop is best around 4500 RPM., if the prop is in good shape. After that I think you start to see blade tip cavitation. You may get a little more MPH. But, not much. If you want to turn a lot more SRPMs then go down in dia. and up in pitch or cup.

Just my thoughts.

Bill

Mini -Tug, KH Tahoe 19 & Bartender 24 - There can be no miracle recoveries without first screwing up.

Tahoe 19 Build

Tahoe 19 Build

- jenko

- Posts: 936

- Joined: Sat Mar 19, 2011 2:50 am

- Location: Pine Mountain . Vic . Australia

- Contact:

Re: Inboard engine builds

I have uploaded a link to my log of the 12 x 13 prop test I can log all data from the engine ecu to my mobile phone,and I can also tune the engine with this app

this screen shot only shows

gps details/map

rpm,speed in kmh,

throttle position %,

injector duty cycle %,

manifold absolute pressure 100% is full throttle,

target air fuel ratio

engine coolant temp deg c

int short term fuel trim, which is how much the oxygen sensor has to adjust the base fuel map to achieve the target air fuel ratio

the adjustment is kept until the battery is disconnected ,but with that knowledge I can permanently correct the base fuel map ,

https://youtu.be/EG-eTILwKJo

I have also attached a pic of the fuel map

With the fueling there was negligible power difference @ full load with an afr of 12:1 to 13.2:1 I did this run at 13:1 but am now running 13.2 :1

I tried to see how lean I could go without loosing power but burnt a hole in the piston due to detonation @ 13.7:1 big oops

this screen shot only shows

gps details/map

rpm,speed in kmh,

throttle position %,

injector duty cycle %,

manifold absolute pressure 100% is full throttle,

target air fuel ratio

engine coolant temp deg c

int short term fuel trim, which is how much the oxygen sensor has to adjust the base fuel map to achieve the target air fuel ratio

the adjustment is kept until the battery is disconnected ,but with that knowledge I can permanently correct the base fuel map ,

https://youtu.be/EG-eTILwKJo

I have also attached a pic of the fuel map

With the fueling there was negligible power difference @ full load with an afr of 12:1 to 13.2:1 I did this run at 13:1 but am now running 13.2 :1

I tried to see how lean I could go without loosing power but burnt a hole in the piston due to detonation @ 13.7:1 big oops

- Mr Hot Rod

- Posts: 1069

- Joined: Thu Mar 03, 2005 2:40 pm

- Location: Chelsea, Quebec, Canada

- Contact:

350 TBI Project

This thread just got a whole lot more complex !

We've been using TunerPro 5.0 (not real time). I may have to upgrade to make tuning a little easier.

Here's a sneek peak at our 350 TBI engine. Somehow we haven't burnt any pistons in it yet !

We'll be marinising the engine in flywheel-forward configuration. We shouldn't have to change the fuel map if we install a 160 degree thermostat.

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

We've been using TunerPro 5.0 (not real time). I may have to upgrade to make tuning a little easier.

Here's a sneek peak at our 350 TBI engine. Somehow we haven't burnt any pistons in it yet !

We'll be marinising the engine in flywheel-forward configuration. We shouldn't have to change the fuel map if we install a 160 degree thermostat.

Dual Turbo mufflers so we can run late at night without disturbing the neighbours.

All that wiring makes a carburetor look simple !

The yellow light is the 'Check Engine Soon' light.

Edit : 27-JUL-2017

Here is the donor vehicle, a 1988 GMC Crew Cab. Purchase price was $500.00 . Body and mechanical

parts and the frame were sold off, so we've recovered our investment and turned a small profit.

Total cost of the engine project : $0.00

I might swap this engine into our plow truck, a 1980 K10 4x4 Long Box (see background).

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

Last edited by Mr Hot Rod on Wed Jul 26, 2017 10:43 pm, edited 3 times in total.

- Bill Edmundson

- Posts: 12618

- Joined: Wed Nov 23, 2005 6:45 am

- Location: Birmingham, AL, USA

- Contact:

Re: Inboard engine builds

Bill

Mini -Tug, KH Tahoe 19 & Bartender 24 - There can be no miracle recoveries without first screwing up.

Tahoe 19 Build

Tahoe 19 Build

- Mr Hot Rod

- Posts: 1069

- Joined: Thu Mar 03, 2005 2:40 pm

- Location: Chelsea, Quebec, Canada

- Contact:

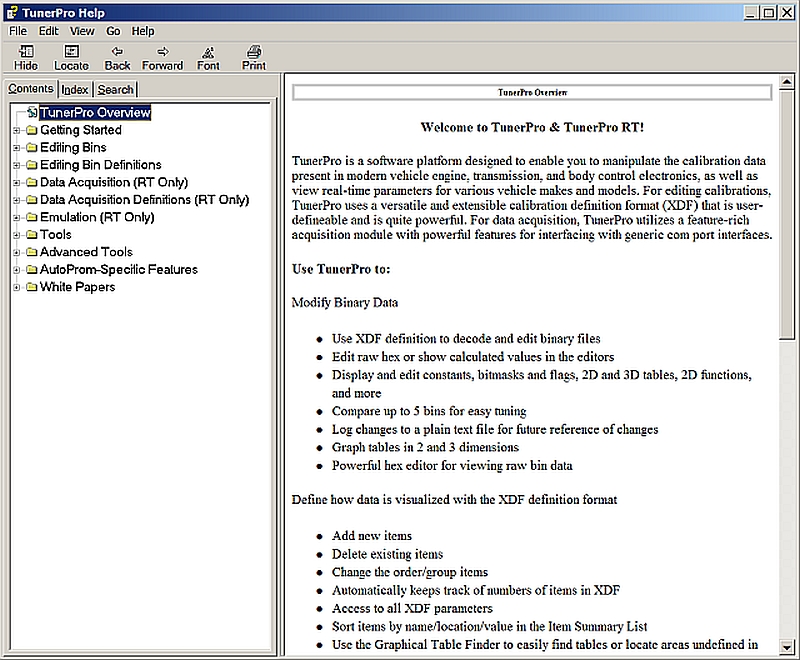

TunerPro Software

I know the feeling, Bill ! It's a little overwhelming, but the documentation is excellent and is easy to understand.

TunerPro is a software platform designed to enable you to manipulate the calibration data present in modern vehicle engine,

transmission, and body control electronics, as well as view real-time parameters for various vehicle makes and models.

A free copy of their software is available on their Website : http://www.tunerpro.net

____________________

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

TunerPro is a software platform designed to enable you to manipulate the calibration data present in modern vehicle engine,

transmission, and body control electronics, as well as view real-time parameters for various vehicle makes and models.

A free copy of their software is available on their Website : http://www.tunerpro.net

- On the Home Page's right hand navigation bar :

- • Click on Overview -> Features & Screen Shots

• Click on Downloads

• Once TunerPro has been installed, click the Help tab -> Help Topics -> TunerPro Overview

- • Click on Overview -> Features & Screen Shots

____________________

Paul Kane

Kane Custom Boats Ltd.

Chelsea, Quebec

Building the Glen-L Hot Rod : http://www.kanecustomboats.com

Glen-L Hot Rod build thread

Kane Custom Boats YouTube channel

Glen-L Boat Video Directory

- jenko

- Posts: 936

- Joined: Sat Mar 19, 2011 2:50 am

- Location: Pine Mountain . Vic . Australia

- Contact:

Re: Inboard engine builds

I don't have much documentation of my engine build but a few pics of building inlet and exhaust manifold and a few other bits

I actually made three inlet manifolds. The first didn't work too well in the low revs, idle was way too high( but looked really cool) , wouldn't let the engine idle below 1200rpm, because of the 12 throttle bodies and lack of flywheel (only using auto flex plate).

So I made one with a common plenum and short runners which solved the height and idle issue,but was showing poor performance in the midrange revs

and the large flat plenum started to show fatigue cracks in the corners after some use.

So the third design was made with longer runners smaller round plenum and fixed all problems.

I actually made three inlet manifolds. The first didn't work too well in the low revs, idle was way too high( but looked really cool) , wouldn't let the engine idle below 1200rpm, because of the 12 throttle bodies and lack of flywheel (only using auto flex plate).

So I made one with a common plenum and short runners which solved the height and idle issue,but was showing poor performance in the midrange revs

and the large flat plenum started to show fatigue cracks in the corners after some use.

So the third design was made with longer runners smaller round plenum and fixed all problems.

Last edited by jenko on Sun Jul 30, 2017 8:27 am, edited 1 time in total.

- jenko

- Posts: 936

- Joined: Sat Mar 19, 2011 2:50 am

- Location: Pine Mountain . Vic . Australia

- Contact:

Re: Inboard engine builds

Making the Exhaust logs was straight forward, I had the holes cut in the pipes by a cnc water blasting shop and flanges cut also.

I had to weld the cylinder pipes to the inner log and slide it inside the outer log position it in the centre and weld, and then weld the flanges on drill holes for water in /out and O2 sensor and weld on appropriate threaded fittings

I ended up with 1/16'' warpage and was able to machine the flange faces on a mill .

I had to weld the cylinder pipes to the inner log and slide it inside the outer log position it in the centre and weld, and then weld the flanges on drill holes for water in /out and O2 sensor and weld on appropriate threaded fittings

I ended up with 1/16'' warpage and was able to machine the flange faces on a mill .

- jenko

- Posts: 936

- Joined: Sat Mar 19, 2011 2:50 am

- Location: Pine Mountain . Vic . Australia

- Contact:

Re: Inboard engine builds

a few of the water plumbing

Re: Inboard engine builds

WOW, that is very impressive work. Thanks so much for sharing.

-

Denon Osterman

- Posts: 558

- Joined: Thu Jun 22, 2006 8:58 am

- Location: toronto, CAN

Re: Inboard engine builds

That is *awesome*, what a gorgeous looking engine! Very unique too - I bet not many boats are driving around with a V12

-

Denon Osterman

- Posts: 558

- Joined: Thu Jun 22, 2006 8:58 am

- Location: toronto, CAN

Re: Inboard engine builds

Hey all,

Guessing it will be a little bit until I get a reply as the forum really seems to dry up in the winter! Nevertheless, I think I've at least gotten a "first pass" at my 496 build for my rampage. What follows is a well researched, utterly inexperienced stab in the dark at something that will do what I want - please, please shoot it down from every angle possible. Keep in mind that budget constraints likely mean I'll actually be finding a junk 454, putting on just heads intake and carb for now, and then re doing the lower end / short block once it croaks...I just can't afford to do all of this "new" if that makes sense.

First and foremost, some background - Im building a rampage, stretched to 20 feet, with an american turbine SD-309 jet pump and AA impeller. I'm building a 454/496 with the goal of getting a "jet friendly" ~500-550 hp at around 5k rpm. I'm pretty dead set on Chevy, particularly because all the accessories I've bought are for a chevy. I'd like it to run on pump gas - preferably 87 but 91 will do - and live a long, long life. Exhaust will be Lighting marine water jacketed headers flowing through a 4" wet outlet. From block up, here's my thinking so far:

-Chevy 454 block, gen VI with the fuel pump mount

-Eagle 496 stroker kit - piston dome / dish / etc will be dictated by overall compression ratio of ~9.5:1 that I'm going for.

-Heads, I'm looking at AFR or Brodix oval port aluminium heads, with chamber size again working with pistons to get me the right compression ratio. Looking at the 265-270 CC size runners.

-Intake, either a Victor Jr or an RPM Air Gap, oval port to match the heads and 4150 style carb mount

-Carb, Holley 850 Double Pumper (probably the marine version).

Notable absent is the cam - I have no idea, and that will take some more time. From my understanding the parts listed above are what will limit or rather allow the engine to make a certain amount of power, and the cam will actually tell it just how much to make. Things I know I have to watch for are exhaust reversion (wet headers), and of course making sure the cam works with the rest of the parts selected. I'll be spending quite a bit of time on the phone with lunati, comp, etc to figure this all out.

Stuff like ignition, oil pan, timing chain, etc etc are all relatively trivial compared to the above as far as I can tell...i.e. I need to spec good parts but they're more the basic necessities than the key ingredients. For what it's worth I'm not planning anything fancy for any of these, but not planning to cheap out either.

As I said, I welcome your thoughts - and if I should start a new topic so I don't drown out this one, happy to do that instead!

Thanks all,

Denon

Guessing it will be a little bit until I get a reply as the forum really seems to dry up in the winter! Nevertheless, I think I've at least gotten a "first pass" at my 496 build for my rampage. What follows is a well researched, utterly inexperienced stab in the dark at something that will do what I want - please, please shoot it down from every angle possible. Keep in mind that budget constraints likely mean I'll actually be finding a junk 454, putting on just heads intake and carb for now, and then re doing the lower end / short block once it croaks...I just can't afford to do all of this "new" if that makes sense.

First and foremost, some background - Im building a rampage, stretched to 20 feet, with an american turbine SD-309 jet pump and AA impeller. I'm building a 454/496 with the goal of getting a "jet friendly" ~500-550 hp at around 5k rpm. I'm pretty dead set on Chevy, particularly because all the accessories I've bought are for a chevy. I'd like it to run on pump gas - preferably 87 but 91 will do - and live a long, long life. Exhaust will be Lighting marine water jacketed headers flowing through a 4" wet outlet. From block up, here's my thinking so far:

-Chevy 454 block, gen VI with the fuel pump mount

-Eagle 496 stroker kit - piston dome / dish / etc will be dictated by overall compression ratio of ~9.5:1 that I'm going for.

-Heads, I'm looking at AFR or Brodix oval port aluminium heads, with chamber size again working with pistons to get me the right compression ratio. Looking at the 265-270 CC size runners.

-Intake, either a Victor Jr or an RPM Air Gap, oval port to match the heads and 4150 style carb mount

-Carb, Holley 850 Double Pumper (probably the marine version).

Notable absent is the cam - I have no idea, and that will take some more time. From my understanding the parts listed above are what will limit or rather allow the engine to make a certain amount of power, and the cam will actually tell it just how much to make. Things I know I have to watch for are exhaust reversion (wet headers), and of course making sure the cam works with the rest of the parts selected. I'll be spending quite a bit of time on the phone with lunati, comp, etc to figure this all out.

Stuff like ignition, oil pan, timing chain, etc etc are all relatively trivial compared to the above as far as I can tell...i.e. I need to spec good parts but they're more the basic necessities than the key ingredients. For what it's worth I'm not planning anything fancy for any of these, but not planning to cheap out either.

As I said, I welcome your thoughts - and if I should start a new topic so I don't drown out this one, happy to do that instead!

Thanks all,

Denon