These details pertain to modifications that may be desired to incorporate a self draining motorwell for the outboard motor & give pertinent dimensions regarding the well and cutout height. The details given are for single short, or long shaft outboard motor 5.5 to 85 HP. A short shaft motor requires a transom height of 15″ ± 1/2″, a long shaft 20″ ± 1/2″ measured vertically from the outside of the bottom planking to the cutout.

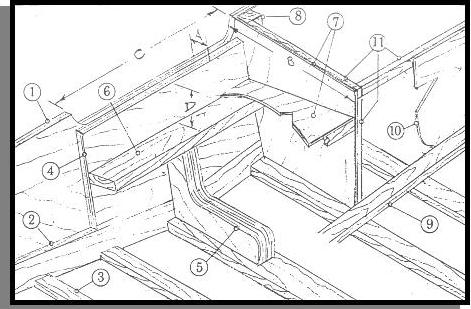

Legend

- Typical transom as detailed in the plans, usually 3/4″ plywood minimum.

- Transom frame per plans.

- Bottom battens as per plans. See #7.

- Motorboard may vary from plans; refer to CHART for size.

- Transom knee per plans, but may need to have upper leg longer or squared off.

- Athwartship 2″ x 4″ screw fasten to knee and through transom with 3″ #14 screws.

- Motorwell sides of 3/8″* plywood butt to the transom, side to the motorwell and bottom batten, and extend forward per the chart. If the spacing of the batten in the plans does not match that required for the motorwell side shift the batten OR add an additional one, notched into the transom and extending at least one and preferably two frames forward. Also 3/8″* plywood motorwell bottom rests on #6 and cleats.

- Provide 2″ x 2″ cleat at junction of #6 to transom.

- A 1″ x 2″ (or laminates to this total) sister frame to support #10, is sprung over and fastened to the battens and keel but ending short of the chine.

- A 3/8″* plywood athwartship bulkhead sides to #9 and butts to the forward ends of #7. Provide openings for access to suit. Fastening to the hull side is not desirable.

- Provide 1″ x 1 1/4″ cleats at junctions as required.

*1/4″ plywood optional for smaller motors.

| HP | “A” Transom thickness | “B” Well depth | “C” Well width | “C” Well width Twins | “D” Clamping area |

|---|---|---|---|---|---|

| 5.5 to 16 | 1 3/8″ to 1 3/4″ | 22″ | 33″ | 54″ | 6″ min. |

| 16 to 61 | 1 3/8″ to 2″ | 22″ | 33″ | 54″ | 6″ min. |

| 61 to 85 | 1 5/8″ to 2 3/8″ | 25″ | 33″ | 54″ | 6″ min. |

| over 85 | 1 5/8″ to 2 3/4″ | 25″ | 33″ | 60″ | 6″ min. |