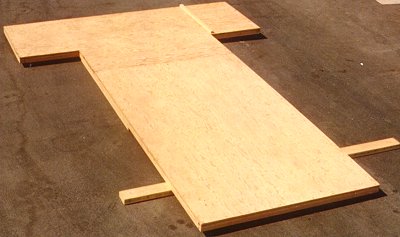

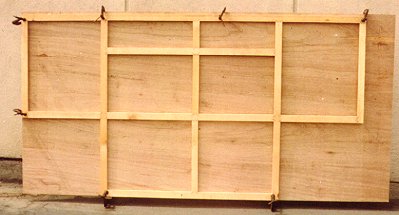

The finished floor unit typical to campers in the 9' to 11' sizes. The 5/8" plywood is glued and fastened to 2" x 2" framework.

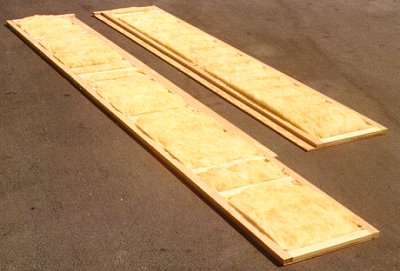

The box side uprights are a "sandwich" structure of 3/8" plywood, 1" framing, and interior plywood paneling (not yet installed). Note the insulation.

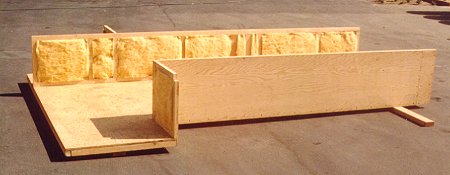

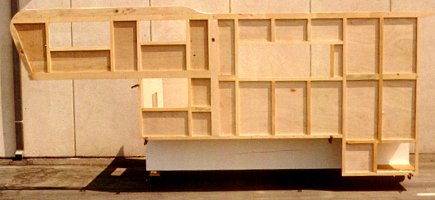

Preliminary mock-up. After the interior panels are installed, the box sides will be glued and fastened in place.

The 3/8" plywood side wings rest on top of the box side uprights and extensions. Note 2" x 2" cleats on outer edge for fastening side walls.

The side wall is built on a base of plywood, directly over the patterns provided.

The second side is assembled over the top of the first side.

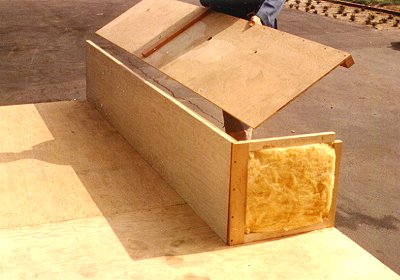

The front wall is covered with interior plywood paneling prior to trimming around the edges and opening with a router or sabre saw.

The side walls are fastened into the longitudinal 2" x 2" cleats on the outer extremity of the side wings. Note the clamps holding the walls in position.

At this point, all interior paneling is installed, framing complete and ready for interior cabinetry, plumbing and electrical. The exterior aluminum will be applied after the interior is essentially complete to allow access to the walls for cutting vent openings and electical.