Building A Goliath By Ed Davis

Posted by Edwin Davis on Sep 3rd 2019

Being New to the Glen-L Family I guess I should start with how I came to this point of life.

Some where in the South Pacific on a Navy ship around 1965 I found a Glen-L Ad for plans in a magazine. I wanted to build just the right boat to fit Me and my life. But I knew that was just a dream. There was no way I could build a boat and the Navy ship it for me from station to station. But some day!

Twenty two years later! I retired, worked in Maryland for 8 years. Then returned to Florida, 20 years as electronic tech., 6 years as Security Guard. Then another retirement.

Just for something to do I built a plywood boat called "Apple Pie". I found it on line at DuckWorks Magazine. It was supposed to be 7'. I used left over shutters from a hurricane the year before. It Is 6' 5". I made the cooper mast out of 3/4" staves for a hollow core. There is an article on "DuckWorks" about the cooper mast.

My next build was a Tug Called "Gill 12" and was really cute. Nice for a day trip but too small for anything else. It got a bad case of rot while I was away on a cruise to New Zealand (with my second wife) and had to be taken to the junk yard. The boat, not my wife!

My third build was" The Lady in Red" by Stephenson Project's. The plans are called Triad it's 12'. Makes a good sail or power boat and can be rowed, if you are so inclined.

A lot of sailors can tie knots, so I gave it a shot for the boat. It looked too plain, so I made some Bow Pudding. Now it will go on my new Tug.

Now! " 2017" In March I ordered the study file for the Goliath. I went thru that and got welding books from the library. Ordered welding book from Glen-L and read thru those. Ordered the full plans and studied them for several days. The wife said it looked good and safe. So "Yes", build a new boat. I explained to Her that it would require several years. She still said OK.

Side note!

I haven't ignored my wife, We went to a wedding in Baltimore, family visit in NY, Caribbean cruise, cruise to Rome, family reunion in SC, trip to Sidney Australia, with cruise to Auckland New Zealand and several day trips here in Florida. Now back to the scheduled program!

In June got a Lincoln welder and some mild steel from Lowes. I did all the welding examples the books said to do. Then took a sample to my metal supplier. The shop man," John", beat my weld with a hammer and it held up. He said "OK, Now get serious"!

I got a friend, a U-Haul trailer, Bought the wood for frames and My first order of aluminum. The "Build" had begun.

It took a couple of days to build the frame. I double checked that the floor was level and the top bars of the frame were level. I was worried about the length available for a build and chose to do just the 18 ft. I could have gone for 20, but went for the safe route.

I laid a piece of 2x4 on the plans, then used an angle guide to mark the angle then chopped that angle. Took it back to the plan and marked the other angle. Then with those two angles chopped the aluminum for length and angle. Five cuts for nine frames grind the joints for 45 deg. then weld, weld, weld.

I'm working in a two car garage with a support post in the middle.

The chop saw on the right with a metal cutting blade was used for all frame cuts thru out the build. I did have to change the blade.

now to make it in 14 alum.

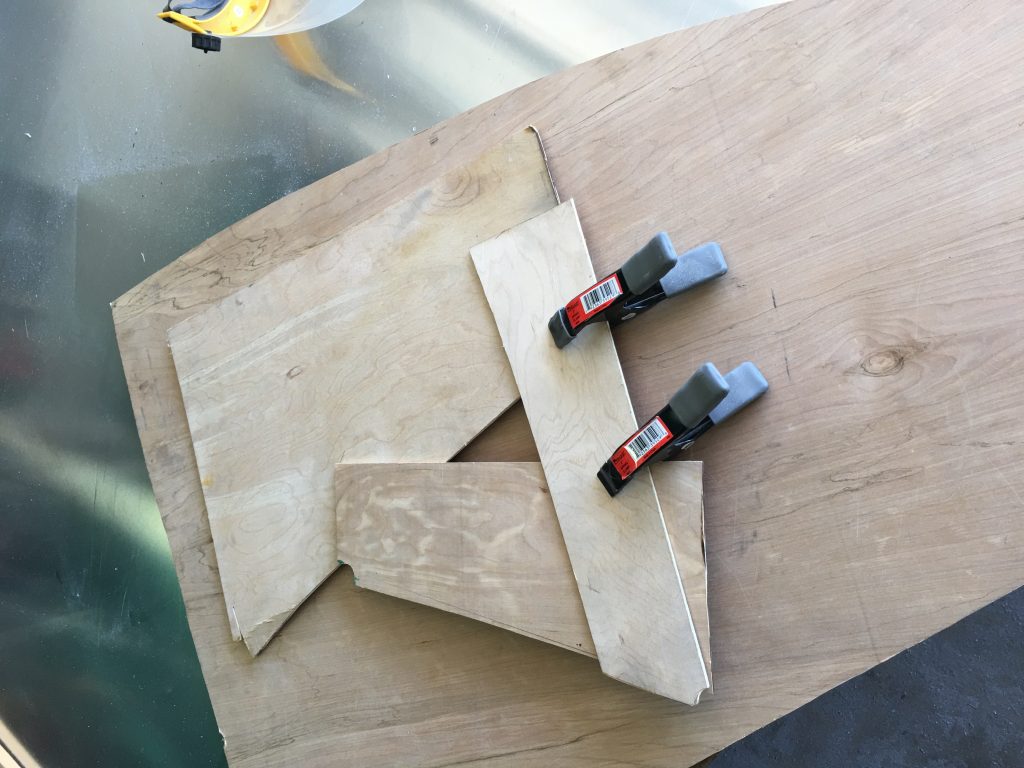

Sometimes there's not a right or wrong way to do something, just what you can come up with to get it how you want.

1/8" door skin for patterns

We're having a hurricane "Dorian". It just left Freeport Bahamas expected to be here in two Days. Hopefully it will stay off the coast about 40-50 miles, as projected. This is the end of my first part and need time to rearrange my mind for part two. I still have a load of pictures. Just need to find them in their various files. As that actor Arnold said " I'LL BE BACK"!