Super Spartan Build on Forum

Posted by Gayle Brantuk on Nov 18th 2011

Since having this blog section of our website, I've been a little conflicted about how best to use it in conjunction with the Forum.

The Glen-L Forum is a very busy and incredible resource for those building boats. Folks discuss different issues and share their projects and photos. It's more of a two-way discussion and has a real community feel to it.

The Blog is our way of dispensing information to everyone through articles and video and whatever else. And it's also for you to share information you've learned about building that will benefit others.

The Forum is all about discussions and often figuring out things together and asking questions. The Blog is more of a way to put information out there--comments can be made, but it's not the same type of discussion as through the Forum.

So, I hope you'll utilize both resources and that they are helpful to you. We're open to any feedback or suggestions too...

Now that I have that off my chest, Roberta has been posting updates on the Forum on her lastest build which is the Super Spartan.

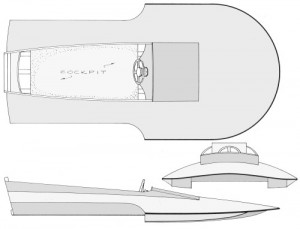

This boat is a 10' hydroplane that is a heck of a lot of fun.

Roberta recently finished building a Zip named Oliver IV. I had the privilege of riding in her boat at the September Gathering and it's just beautiful.

Roberta is a real craftswoman and is also very kind about posting build updates on the Forum.

I don't know if you folks realize what a resource this is for you. She is actually showing you her build, step-by-step.

So, I thought I'd direct you to her build so you can follow along too. Here are her first couple of entry and then a link to the rest. Enjoy...

Tuesday, November 15, 2011

I glued up the bottom plank today. If I had a 4'X10' panel, the butt joined panel would not be necessary, but I didn't so I layed up the parts and glued and screwed it on the table. The blocks will ensure the joint is nice and flat.

Earlier I ripped the bottom battens and chines. I had some left over white oak, so I used that for the chines. Menards, a local Wisconsin version of Home Depot, had some decent Philipine mahogany I purchased for the battens.

The chines have a 45 deg. bevel on the sides for the side planking and I also rounded over the inside edges on those as well as the edges on the bottom battens for pilot comfort.

I needed one more 6 mm Okoume panel for the rest of the bottom planking and runner planks, so I was able to pick that up at a place called Kettle Moraine hardwoods. They have two locations in SE Wisconsin. One in Caledonia and one near Hartford. They stock a lot of good hardwood and also stock marine plywood like the Okoume and Maranti.

I think I will use the Maranti 4 mm for the deck as it is a little darker than the Okoume and will match the mahogany better. I plan to paint the bottom white unless I do a really perfect job on the planking. Ahhh, paint covers a multitude of sins!!!

This boat build uses no building form, but the instructions need to be followed in order to get it all together properly. I will follow them with great intrepidation.

Wednesday, November 16, 2011

Today I layed out the lines to position screw holes for the chines, battens, and runner chines. The joint I did yesterday turned out great with just a little sanding to remove some glue runoff. I used a scrap piece of plywood when drilling all the holes to minimize tearout and I mildly countersunk all the holes that would need some filling to cover the screw heads. This worked well on the Zip, but you can't overdo it.

I also cut the aft sides as the plans recommend attaching them to the aft chines before installing them. There is a 45 deg bevel on the chines and once the side planks are attached, I will bevel the plank to match the chine. Then these will be installed with the frame members and sheers. I will install the battens tomorrow.

I clamped the runner chines in position and drilled a locating hole in the aft end. Then I removed the chines for gluing. I put a generous amount of glue on the bottom plank, then reclamped the chines to it one at a time. The locating hole was screwed in first and the assembly was flipped to make it easier to install the screws. I drilled the holes two or three at a time and installed the screws going from aft to the bow. The reason I did this was because the runners have an arc to them and I did not want a bubble in the plywood bottom along the joint. Then I repeated the process for the other runner.

Here are some pics of todays progress.

You can track the rest of Roberta's build on the Forum and join in the discussion. She does beautiful work folks, so this is really one to watch! Thank you Roberta!